Operating Principle

A choice of two systems:

– Water filled rubber dams providing continuous reservoir level control

– Air inflated rubber dams where speedy regulaton is needed

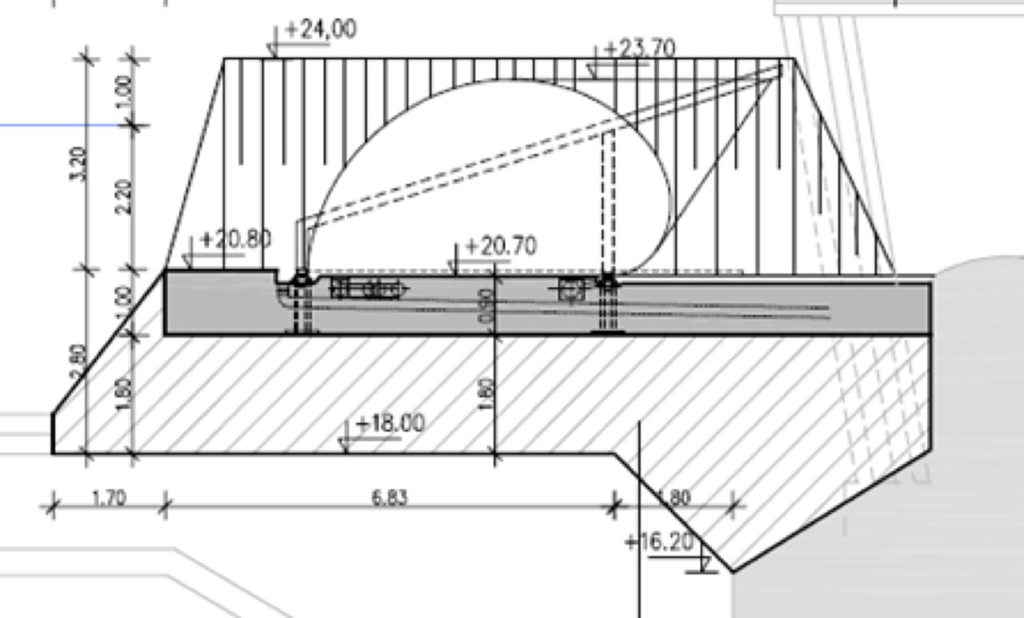

For the Air inflated system an air blower discharges pressurised air into the rubber dam trough a pipe system linked to the control shaft. The control shaft houses the blower, the control equipment and the motorized air flaps and pressure relief valves for regulation and control. Air pressure can be released trough the valves allowing the rubber body to drop downwards to the weir sill.

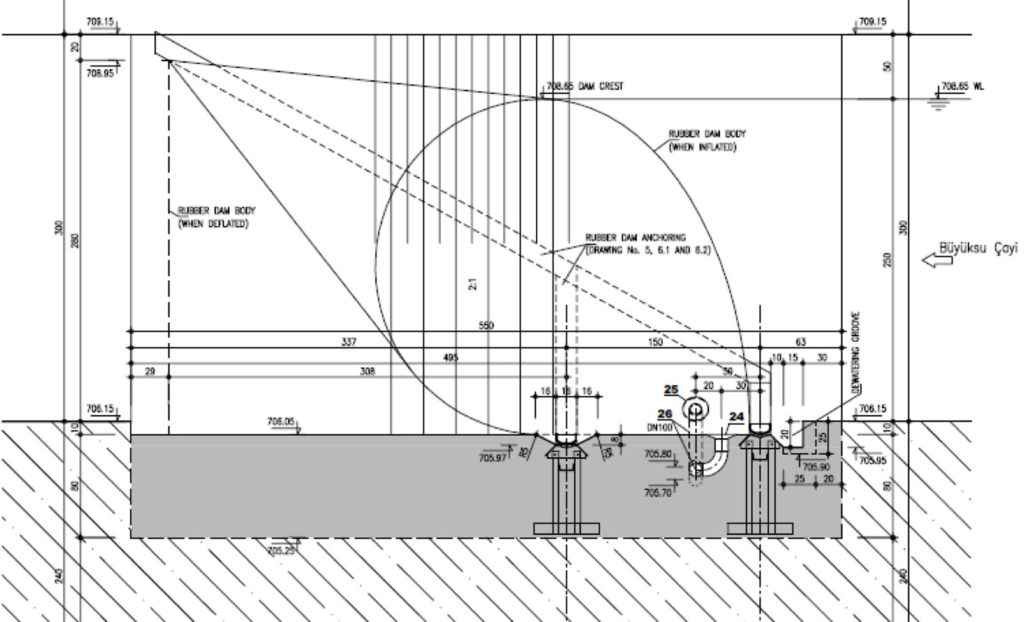

For the Water filled sytem a pump discharges water into a filling shaft linked by pipework to the body of the dam. The shafts are equipped with a device regulating the reservoir level. Using a drainage pump or outlet valve the rubber dam ca be lowered downwards continuously until its body drops completely to the weir sill.

Water is pumped through a pump shaft into a filling shaft which is linked via a tube as a “communicating container” with the control shaft. The latter is fitted with a water-level regulating installation.

Example water filled system

Example air inflated system